Amandine Rousset 1, 5, Ali Amor 2, 3, Teerasak Punvichai 4, Sandrine Perino 5, Serge Palu 2, Michel Dorget 1, 3, Daniel Pioch 2 and Farid Chemat 5

1 GuaTecs, 28 rue Xavier Bichat, 72000 Le Mans, France;

2 UR BioWooEB-Biorefinery Team, CIRAD, 34398 Montpellier, France;

3 CTTM, Centre de Transfert de Technologie, 72000 Le Mans, France;

4 Faculty of Science and Industrial Technology, Prince of Songkla University, Surat Thani, Thailand;

5 Avignon University, INRAE, UMR408, GREEN Extraction Team, 84000 Avignon, France;

Indeed, natural rubber shows better dynamic properties, especially resilience – the ability to undergo big deformations without breaking and to recover its initial form when the constraint is released - as well as very good resistance to abrasion, shock and tearing.

More than 2000 plants produce PI. The best-known plants for their potential commercial interest are part of the families of Euphorbiaceae (Hevea, Bentamia, Manihot), Asteraceae (Parthenium argentatum, Taraxacum kok-saghyz) and Sapotaceae (Gutta percha, Argania spinosa). Among the most promising ones are Kazakh dandelion (Taraxacum kok-saghyz) and guayule (Parthenium argentatum). This article will focus on guayule.

Guayule, also called “yerba de hule” is native to the desert of Chihuaha, located in Mexico (Zacatecas, Coahuila, Chihuahua, San Luis Potosí, Nuevo León and Durango) and southern Texas in the United States. Native plants can live up to 30-40 years or more. It resists to temperature higher than 40°C and can withstand temperatures below -15°C.

Guayule is adapted to hot desert environments and to sites with different soils (shallow, stony, calcareous and friable) and with relatively low concentrations of nutrients, but it grows best in well-drained soils and cannot tolerate waterlogging.

PI and/or resin are found in different sections of the stems, branches, roots, leaves and flowers. On average, there are 8% of PI and 10% of resin in the plant. Natural rubber is contained in thin-walled cells, the parenchyma cells, located in the bark and the pith.

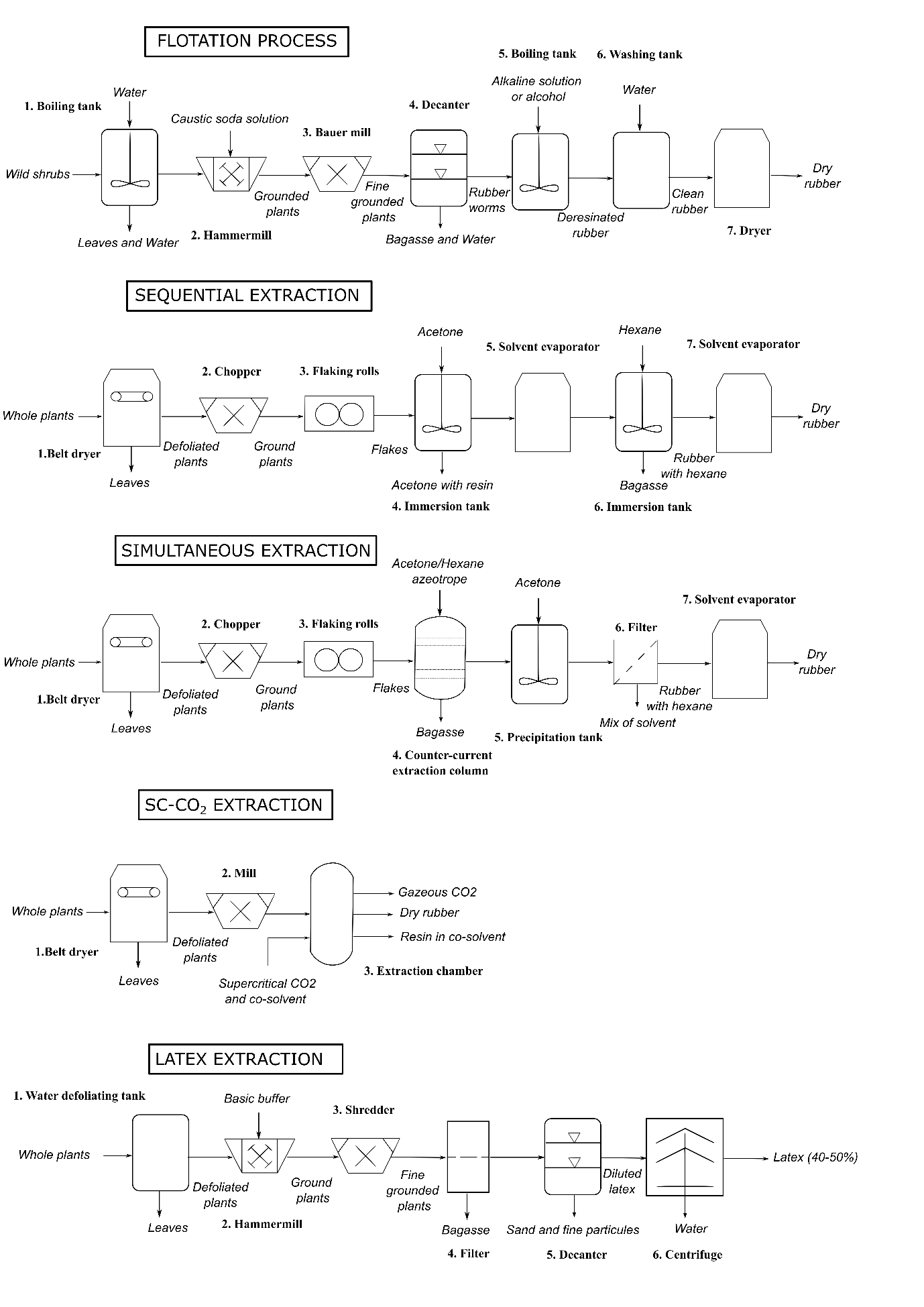

There are two major types of processes for guayule’s PI extraction: processes that extract PI in a coagulated state, the aim being to obtain dry rubber (i.e. for tyres) and processes that extract PI in the emulsion form (i.e. latex for gloves). The main processes to obtain dry rubber are: flotation (aqueous process), sequential extraction (solvent process), simultaneous extraction (solvent process), and more recently supercritical-CO₂ (with co-solvents). To extract PI in the emulsion form, an aqueous process was developed and improved progressively.

Industrial processes to extract rubber and latex from guayule plants

Industrial processes to extract rubber and latex from guayule plantsDepending on the used process, products and co-products are different: dry rubber or latex, resin, leaves (if the plant has been defoliated) and bagasse.

Proposed applications for products and co-products of guayule processing

Proposed applications for products and co-products of guayule processingGuayule plant image source: https://www.britannica.com/plant/guayule#/media/1/248122/106398

SWOT Analysis of guayule development

SWOT Analysis of guayule development